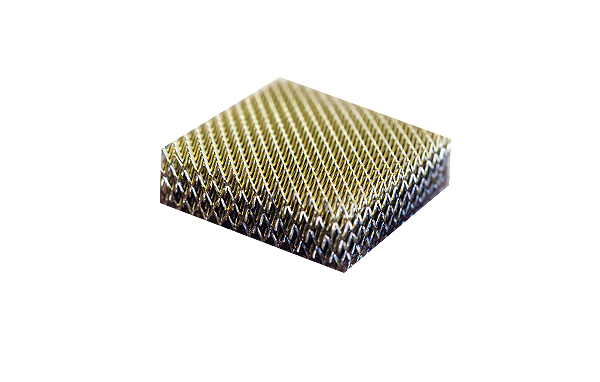

Nickel-Phosphorous Lattice

Bringing aircraft technology into construction to make lighter buildings.

Nickel-Phosphorous Lattice is an ultralight lattice. The material is 100 times lighter than Styrofoam; it is one of the lightest structural materials in the world. The thickness of the material is 100 nanometres which makes it 1000 times thinner than human hair. It is composed of 93% nickel, and 7% phosphorous. It can receive 50% strain without permanent deformation and exhibits high strength and elasticity. A 3D lithographic printer coats diamond-shaped polymeric templates with electroless nickel–phosphorus (Ni–P).

The compressive strength of nickel-phosphorous lattice recorded in recent testing in Beihan University,China, reached 1.08 MPa for a composite with a density of 240.4 kg per m3 and a phosphorus content of 8.01 % of its total weight Steel, in comparison, is approximately 8,050 kg/m3 with a compressive strength of 250 mPa, which makes it around 6.9 times stronger in compressive strength on average than this microlattice.

Benefits and Drawbacks

Nickel-Phosphorous Lattice is ultra-lightweight which enables it to be resource-efficient. It can be used for acoustic damping or vibration/shock-absorption applications. It has a higher strength and a much higher elasticity (50% deformation) compared to materials with the same density.

Commercial Readiness

Boeing is currently in the research and development phase of manufacturing the material. Boeing is speculating on the material’s usage for airplanes and automobiles. Due to the material’s compressive strength, it could be used for lightweight structural components of commercial construction.